15 Common Reasons for Hydraulic Repair Service in Construction Equipment

- sylvia6175

- Jul 16, 2025

- 4 min read

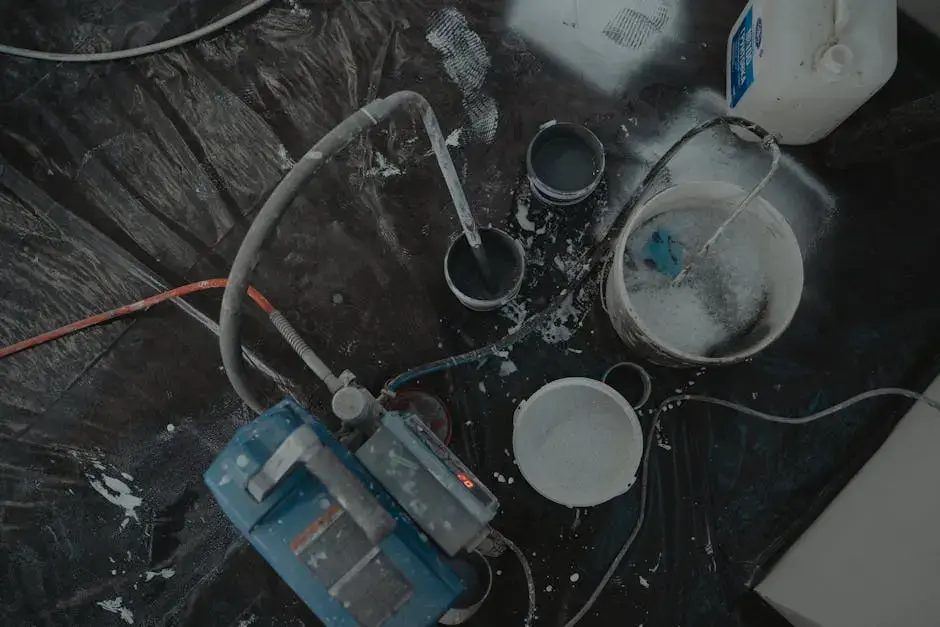

When it comes to construction equipment, keeping hydraulics in top shape is essential for smooth operation. Hydraulic systems are the heart of many machines, and neglecting them can lead to costly downtime and repairs. In this blog, we’ll explore the most common reasons why hydraulic repair service might be needed, helping you identify issues before they become major problems.

1. Leaking Hydraulic Fluid

Leaks in hydraulic systems can significantly reduce efficiency and pose safety hazards on job sites. A small crack or loose fitting can quickly escalate into a major problem, leading to equipment downtime and costly repairs. Therefore, identifying the source of the leak is crucial for a timely repair.

Regular inspections should focus on hydraulic lines, cylinders, and fittings, as these are common areas for leaks to develop. Using the right tools and techniques, you can locate and fix leaks before they become severe. Moreover, monitoring hydraulic fluid levels can help in detecting slow leaks that might otherwise go unnoticed.

2. Overheating Components

Overheating in hydraulic systems can stem from excessive usage or inadequate cooling mechanisms. Just like an engine, hydraulic systems require optimal temperature control for efficient performance. When components overheat, it can lead to faster wear and tear and eventual system failure.

Regular monitoring of temperature gauges and fluid conditions can help catch overheating issues early. Implementing proper cooling methods, such as installing additional cooling fans or ensuring that the hydraulic fluid is of high quality, can prevent overheating crises that disrupt projects.

3. Contaminated Hydraulic Fluid

Contamination is often an unseen enemy in hydraulic systems. Debris, dirt, and other contaminants can enter the hydraulic fluid and disrupt system performance. Such disruptions can lead to various mechanical issues that eventually require hydraulic repair services.

That’s why regular fluid changes are key to maintaining system health. Not only does clean hydraulic fluid optimize performance, but it also extends the life of other components such as pumps and actuators. It’s a proactive step that pays off in reliability and efficiency.

4. Worn Seals and Gaskets

Seals and gaskets are vital components that wear down over time. When they degrade, leaks can occur, leading to reduced efficiency of the hydraulic system. The good news is that they are usually straightforward to replace, but it's crucial to keep an eye on these components.

Regular inspection schedules can catch wear and tear before they escalate into costly repairs. Additionally, using high-quality seals and gaskets during replacements can mitigate future issues and enhance overall system performance.

5. Faulty Hydraulic Pumps

Hydraulic pumps are the powerhouses of hydraulic systems, providing the pressure needed for equipment operation. However, when a pump malfunctions, it can lead to significant operational problems that require immediate attention.

It’s essential to recognize the signs of a faulty pump. Unusual noises, fluctuating pressure readings, or decreased performance are all red flags. Regular maintenance and timely repairs ensure that the heart of your hydraulic system remains in top condition.

6. Deteriorated Hoses and Lines

Flexible hoses are prone to wear and tear over time. They are essential for carrying hydraulic fluid under high pressure, and any deterioration can lead to leaks or ruptures. Regular inspections can help catch hose deterioration before it affects your system.

Be sure to look for signs like cracks, bulges, or fraying. Replacing hoses at the first sign of wear is not just advisable; it can be a lifesaver for your equipment’s functionality.

7. Improper System Lubrication

Maintaining the correct lubrication levels is critical for hydraulic efficiency. Inadequate or excessive lubrication can hinder performance, affecting the overall lifecycle of components.

It’s important to understand how lubrication works within your specific hydraulic system. Regular checks and adherence to manufacturer specifications will ensure optimal operating conditions, keeping performance smooth and effective.

8. Cavitation Issues

Cavitation can occur when there's insufficient fluid reaching the pump, leading to potential damage. This phenomenon can create an air pocket, resulting in noise and loss of hydraulic pressure.

Understanding how to prevent cavitation involves monitoring fluid levels and ensuring proper system design. By maintaining adequate fluid levels and avoiding abrupt throttle changes, you can keep cavitation problems at bay.

9. Electrical Failures Affecting Hydraulics

In modern construction equipment, electrical problems can significantly impact hydraulic functions, particularly in electronically controlled systems. A blown fuse or faulty wiring can lead to a variety of hydraulic malfunctions.

Troubleshooting electrical failures promptly can save time and prevent operational delays. Regular checks of the electrical systems should be part of a comprehensive maintenance program.

10. Inadequate Maintenance Practices

Inadequate maintenance practices can lead to various hydraulic issues that could have been easily prevented. A lack of regular inspections means potential problems go unnoticed, which could ultimately escalate to significant repairs.

Establishing a routine maintenance schedule is vital for performance and longevity. It’s the best way to catch small problems before they balloon into costly repairs.

11. Excessive Wear on Cylinders

Hydraulic cylinders can wear unevenly, leading to leaks and inefficiencies in your machinery. This issue often goes unnoticed until the performance drop is significant.

Regular monitoring of cylinder conditions and replacing worn-out parts proactively can help ensure smooth operation. Anticipating these needs enhances equipment reliability and overall project efficiency.

12. Damaged Hydraulic Filters

Hydraulic filters are critical in maintaining system performance. Clogged or damaged filters can severely impact the operation by allowing contaminants into the hydraulic fluid, wreaking havoc on the entire system.

Regular filter changes are crucial to keeping your system functioning well. A simple task can yield significant benefits by protecting the system from unnecessary wear and tear.

13. Incorrect Installation of Components

Incorrectly installed components can lead to leaks, malfunctions, and complications that affect system performance. It might seem tedious, but ensuring that installations are done correctly is fundamental.

Always double-check installations and follow manufacturer guidelines to avoid future repairs. Prevention is always cheaper and more efficient than correction.

14. Inconsistent Operating Conditions

Inconsistent operating conditions can strain hydraulic systems, leading to premature wear and failure. For example, fluctuating temperatures or load demands can impact how your hydraulic system performs.

Understanding how these conditions affect performance is crucial. Adapting operational practices to suit the prevailing conditions can help ensure optimal system performance.

15. User Error and Mismanagement

Lastly, user error and mismanagement can lead to hydraulic issues that might seem trivial at first but can snowball into major problems. A lack of training or awareness among operators can result in mistakes that affect performance.

Investing in training for operators can help minimize user error and ensure that equipment runs smoothly. After all, well-informed operators are key to maintaining hydraulics effectively.

Comments